It is vital to grasp when to choose tighter tolerances to your section-maker. Whilst restricted tolerances usually are not needed for the whole merchandise, significant structural parts, such as people who healthy into other elements, need minor deviation from your nominal value because inaccuracy can jeopardize the component’s integrity.

Regularity and Repetition: CNC machines offer you dependable replications of equivalent parts with actual specs each time, making them The perfect Alternative for mass production. In spite of complex designs, CNC machining guarantees each component continues to be much like its predecessor in appearance.

In order for you the greatest success, you must have interaction with a dependable CNC machine small business by having an in-house engineering Section. AT Machining features experienced industry experts who are very well-versed in CNC precision machining treatments. Ask for a estimate nowadays for prime-notch CNC precision machining providers.

The applications of CNC systems in these sectors are large, from intricate customized designs for weapon bodies to a missile’s internal elements. Here are a few of the parts that are made using a CNC manufacturing approach:

Quite a few of those parts overlap with other industries including aerospace and electronics. The flexibility of CNC machines to provide on-need replacement parts and upgraded parts are significantly valuable On this industry. Consequently, it works effectively for parts that demand frequent innovation and safety.

In considering the fact that-taken off corporation webpages, Bredikhin explained his organization as being a “Russian department” of I Machine Tools. The description is one of numerous indicators that the businesses are relevant.

An organization that designs custom parts for your automotive industry could possibly utilize a hybrid manufacturing system to develop complex geometries and intricate parts. The method begins with 3D printing, where a polymer material is used being a base layer. Then, CNC machining refines and shapes the ultimate element. This combination of procedures permits greater structure adaptability than both system could reach By itself.

Pc Aided Manufacturing (CAM) program employs two types of codes: G and M codes. The G code regulates the cutting tool’s coordinates. The M code manages the machine’s auxiliary capabilities, such as turning on or from the coolant circulation.

Designers generate CAD styles for every signage project and turn them into a CAM CNC plan, which then operates the machine. This enables CNC machines to recreate any lettering models, sizes, and fonts for signage assignments.

The method also here eliminates the necessity for handbook assembly and boosts the production speed in comparison to common procedures. Once the look is entire, the component is usually tested and evaluated to be used in automotive applications. The hybrid manufacturing course of action will allow organizations to scale back expenses even though producing high quality parts immediately and efficiently.

The die and mildew industry has relied on CNC machines Because the seventies, with steady advancements in precision and speed. The introduction of 5-axis CNC machines has authorized for the production of extra complex molds, reducing direct periods and enhancing product or service high quality.

“I believe us meeting and attending to know one another was actually fortuitous,” Bredikhin stated on online video.

From the 1970s, CNC technology experienced evolved Together with the introduction of pcs, letting for more complex and precise Charge of machining operations.

For the most part, The solution to how these items are developed is similar - precision CNC machining. CNC strategies happen to be the foundation stone for modern businesses, making parts within an automated vogue at unbelievable production speeds.

Devin Ratray Then & Now!

Devin Ratray Then & Now! Amanda Bearse Then & Now!

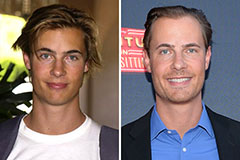

Amanda Bearse Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now!